Our House—About the Siding

>> Wednesday, December 31, 2008

When I did the post concerning our house I mentioned that I’d have more to say later about the siding. So, let me tell you about our siding.

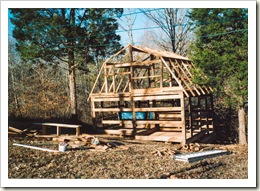

During the Summer of 2004 while we were working on the house I had heard about the “cull wood” or barn lumber (like what I used to build our goat barn) and was trying to find where I could buy it. I called a company listed in the phone book as “Anderson Forest Products.” I didn’t know just what they did, assuming that they might be a sawmill. As it turned out they manufacture wooden pallets. When I asked the receptionist about “cull wood” she told me that the only thing they had was what they referred to as “slabs.” I asked her what they were charging for that, not knowing exactly what it was. She told me they were getting $2.00 a bundle. For that price I figured there must be some use I could make of these “slabs.”

When I went to buy some I discovered that the “slabs” were pieces that were rejected in their manufacturing of the pallets. Some had a bad or rotten spot, others might be a bit thin or a bit thick. Some were cut thicker on one end than the other. Some were totally unusable but most could be used in some manner. They were approximately 1/2 inch thick by about 3-4 inches wide and 36, 40 or 48 inches long. A bundle consisted of all they could bind onto a wooden pallet.

The first project where I used some of these pieces was in the construction of a small shed to house a calf. There were many thoughts as to possible usage. I occurred to me that they might be used as siding. I knew that cedar shingles have been used for siding for many years. These pieces were mostly oak and poplar. Anyway, I decided to try using them in that way.

I used a cut-off saw to cut pieces 18” long. I bought a pneumatic stapler to use in attaching the “shingles”. I overlapped the pieces leaving 8” showing. So, I was putting a double thickness of the wood onto the house.

Here is a close view of the siding. Some of these boards were a bit wider than the 3-4 inches. Starting at the bottom and working up all of the staples are hidden. I did not put any type of paint or treatment on the boards and over time they are weathering and turning grey, which is kind of what we wanted. We feel that the look is fitting for the location and area in which we live.

Here is a close view of the siding. Some of these boards were a bit wider than the 3-4 inches. Starting at the bottom and working up all of the staples are hidden. I did not put any type of paint or treatment on the boards and over time they are weathering and turning grey, which is kind of what we wanted. We feel that the look is fitting for the location and area in which we live.

Comparing this picture with the one posted earlier you can see that the siding is much darker than when first applied. In the above picture the wood still has a fresh look to it. It was applied onto the pantry and has not been exposed to the rain and sun for as long.

In addition to the siding I used these pallet “slabs” for a few other applications on the house.

Pallet piece were used for the balusters in the railing for the deck and the front porch. I also used the material for the soffits all around the house. Here is view of the soffit on the side of the house.

The pallet “slabs” have worked well and the cost has been very reasonable. I sent about $30.00 on the pieces to completely side the house—of course I spent almost $100.00 on staples! Darryl is planning to use this same siding technique on his house.