All-American Pressure Canner

>> Friday, February 5, 2010

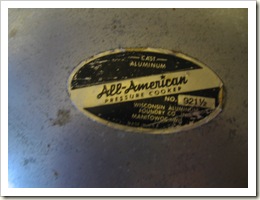

Shortly after we were married we began doing some canning but it was mostly fruit for which we used a water bath canner. But, by 1973 we had other items to can which needed to be processed in a pressure canner. We went to buy one but for some reason they were in short supply. We placed an order with Sears and one with Montgomery Wards planning to accept whichever one came first and cancel the other order. The Wards order came in first, an All-American 921-1/2. The current 921 appears to be the same canner. As far as we can remember we paid about $40.00 for our unit, which seemed like a lot of money then. Now, the list price is $210.00!

A couple of years ago it was brought to our attention that the new All-American canners (as well as some other brands) were using a regulator weight which allowed the pressure to be held. This is achieved by the excess pressure causing the weight to jiggle and allowing steam and pressure to escape.

I did some checking and found that I could order a weight and a vent pipe that would replace the petcock. This change has made canning much less of a stress in that once the pressure is arrived at one knows that it won’t go higher and can even walk away from the canner for a period of time.

Pictured here to the right is the petcock I removed. To allow the steam to vent the top piece was turned straight up and down. Once steam was escaping it was turned over as pictured and the pressure was able to build up.

The pressure gauge is still in use. It easily verifies where the pressure is. Also, one never wants to remove the lid until all pressure is down. Once zero pressure is arrived at the weight can be removed which would allow any small amount of steam and pressure to escape before the lid is removed.

If we just had a dollar for each jar of food that has been processed in that All-American canner in the last 37 years we might be able to take that cruise we often talked about!

4 comments:

We got a new AA canner 2 years ago (I think) and paid a pretty penny but it is far superior to the cheap ones we had been using...I only hope mine will last as long as yours!

Thank you so much for this info. I have an AA 925 with the old pet cock and want to convert it to a weighted jiggler. It seems that you indicate that the threading for the petcock matches the threading on the valve stem currently availble and its just that that I am trying to determine before making any purchases.

Does your lid have an overpressure valve? Recently acquired an old AA 925 w/ petcock! I will change, but am unable to locate info as to if these older canners lacked an overpressure valve. They sound important! Thanks

Celine, when using the canner as you have it the petcock will automatically "pop-off" at 20 lb. of pressure. With the weight the pressure is let off at the setting of the weight. Once the heat is off and the canner cools down the pressure is slowly released. The main thing one needs to be sure of is that the opening doesn't become clogged and not let the steam out. The book that came with the canner suggests using a toothpick to keep it clean and open. Hope this helps.

Post a Comment